Products Ranges

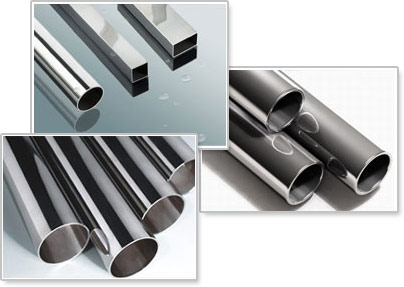

The pipes our company supply and export are of superior quality and assure the clients a longer working life of our product. Having smooth surfaces both inner and outer, our products are also flexible, durable and corrosion resistant. The product exhibits high metallurgical properties and are usually used in for applications in the oil & gas and (petro)chemical industries.

(GI/CS/SS/Cu Ni/Alloy steel/Haste alloy /Boiler tubes etc.)

Pipes and Fittings Standards/Codes: ASME/ANSI/API/ ASTM, DIN, BS, ISO.

Pipes and Fittings suppliers: APOLLA STAINLESS STEEL, MAKE: INDIA, UK, USA, KOREA

|

Range:

|

| 15 mm NB up to 1200 mm NB in Schedule 5S , 10S ,10, 20 , 40S , 40 , STD , 60 , 80S , 80 , XS , 100 , 120 , 140 , 160 & XXS |

|

Form: |

|

Seamless / ERW / Welded in Round & Square.

|

|

Stainless Steel:

|

|

Grade: 304, 304L, 304H, 309, 310, 310S, 316, 316Ti, 316 L , 317, 317L, 321, 347, 347 H, 904L

|

|

Duplex Steel:

|

|

Grade: 2205 (UNS No. S31803), 2207 (UNS No. S32760)

|

|

Nickel Alloy: |

|

Grade:Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201),Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500), Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020), Titanium (Grade I & II) |

|

Copper Alloy: |

|

Grade:UNS No. C 10100, 10200, 10300, 10800, 12000, 12200, 70600, 71500, UNS No. C 70600 (Cu -Ni- 90/10), C 71500 (Cu -Ni- 70/30) |

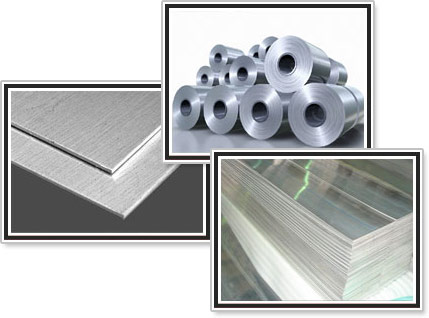

Sheet And Plates (Al/GI/CS/SS/Cu Ni/Alloy steel/Haste alloy etc.)

Coils ( GI/CS/SS)

|

Stainless & Duplex Steel

|

|||||||||||

|

RANGE

1 MM TO 200 MM THK IN 1000 MM TO 3000 MM WIDTH x 2500 MM / 5000 MM / 10000 MM / COIL. |

|||||||||||

|

|||||||||||

|

Carbon & Alloy Steel

|

||||||||

|

RANGE

1 MM TO 200 MM THK IN 1000 MM TO 3000 MM WIDTH x 2500 MM / 5000 MM / 10000 MM / COIL. |

||||||||

|

||||||||

|

Nickel & Copper Alloy

|

||||||

|

RANGE

1 MM TO 200 MM THK IN 1000 MM TO 3000 MM WIDTH x 2500 MM / 5000 MM / 10000 MM / COIL. |

||||||

|

||||||

(GI/CS/SS/Cu Ni/Alloy steel/Haste alloy etc.)

|

Stainless & Duplex Steel

|

||||||||

|

||||||||

|

Carbon & Alloy Steel

|

|||||||

|

|||||||

|

RANGE 15 NB UP TO 1200 NB IN SCH 5S , 10S ,10, 20 , 40S , 40 , STD , 60 , 80S , 80 , XS , 100 , 120 , 140 , 160 & XXS

FORM :: SEAMLESS & WELDED LONG RADIUS & SHORT RADIUS ELBOW 90 DEG , LONG RADIUS ELBOW 45 DEG ,Long Radius & Short Radius Elbow 90 Deg , Long Radius Elbow 45 Deg , Long Radius & Short Radius Elbow 180 Deg ( Return Bend ) , Reducing Elbow , Equal Tee , Un Equal Tee, Crosses , Concentric Reducer , Eccentric Reducer , Long Stubend , Short Stubend , Coller , Pipe Cap , Long Radius Bends R =3 D , 5 D , 6 D , 8 D ,10 D & 20 D In 15 Deg ,30 Deg, 60 Deg & 90 Deg And Drawing Bassed Butt Weld Fitting ( Customised ) . |

|||||||||

|

Nickel & Copper Alloy

|

|||||||||

|

|||||||||

|

RANGE

15 NB UP TO 100 NB IN 2000 LBS , 3000 LBS , 6000 LBS & 9000 LBS , 150 LBS , 250 LBS. FORM :: SOCKET WELD FITTINGS :: ELBOW 90 DEG , CROSS , TEE , ELBOW 45 DEG , COUPLING , HALF COUPLING & CAP |

|||||||||

|

Nickel & Copper Alloy

|

|||||||||

|

|||||||||

|

Stainless & Duplex Steel

|

||||||||

|

||||||||

|

Carbon & Alloy Steel

|

|||||||

|

|||||||

(GI/CS/SS/Cu Ni/Alloy steel/Haste alloy etc.)

|

Stainless & Duplex Steel

|

||||||||

|

||||||||

|

Carbon & Alloy Steel

|

|||||||

|

|||||||

|

RANGE

15 NB UP TO 600 NB IN 150 LBS , 300 LBS, 400 LBS , 600 LBS , 900 LBS , 1500 LBS , 2500 LBS / TABLE 2.5 , TABLE 6 , TABLE 10, TABLE 16,TABLE 25 , TABLE 40, TABLE 64, TABLE 160, TABLE 320, TABLE 400 FORM SLIP ON , SOCKET WELD , BLIND , LAPPED , SCREWED , WELD NECK , REDUCING , SPECTACLE ,SLIP ON BOSS , PLATE , PLATE BLANK , SCREWED BOSS. |

|||||||||

|

Nickel & Copper Alloy

|

|||||||||

|

|||||||||

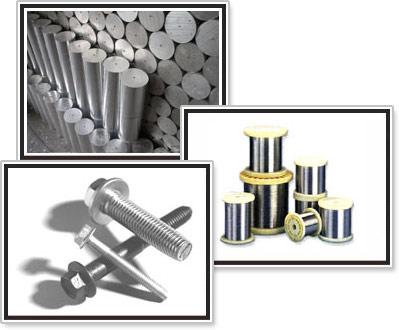

(All material and grade)

We Supply a wide range of high quality steel round bars. Available in different shapes these bars are supplied using superior grade steel. These are used in diverse industries such as automobile petro- chemical and energy industry etc. These bars are available in stainless steel, nickel alloys and other ferrous & non-ferrous metals.

|

Range:

|

|

3.17 mm to 350 mm Diameter

|

|

Form:

|

|

Bright / Black / Forged in Round, Square & Hex.

|

|

Stainless Steel:

|

|

Grade: 304, 304L, 304H, 309, 310, 310S, 316, 316Ti, 316 L, 317, 317L, 321, 347, 347 H, 409, 410, 410S, 420, 430

|

|

Duplex Steel:

|

| Grade: 2205 (UNS No. S31803), 2207 (UNS No. S32760) |

|

Nickel Alloy:

|

|

Grade:Nickel 200 (UNS No. N02200), Nickel 201 (UNS No. N02201),Monel 400 (UNS No. N04400), Monel 500 (UNS No. N05500),

Inconel 800 (UNS No. N08800), Inconel 825 (UNS No. N08825), Inconel 600 (UNS No. N06600), Inconel 625 (UNS No. N06625), Inconel 601 (UNS No. N06601), Hastelloy C 276 (UNS No. N10276), Alloy 20 (UNS No. N08020), Titanium (Grade I & II) |

|

Copper Alloy:

|

|

Grade:UNS No. C 10100, 10200, 10300, 10800, 12000, 12200, 70600, 71500, UNS No. C 70600 (Cu -Ni- 90/10), C 71500 (Cu -Ni- 70/30)

|

Stainless Steel: ASTM A 409, A 182, A276

Grade: 304, 304L, 304H, 316, 316L, 316Ti, 321, 321H, 317, 317L, 310, 310S

Carbon Steel: A105, ISO 2062

Alloy Steel: A182, Gr. F1, F2, F11, F22, F5, F9, F91

Nickel Alloys: B162, B127, B463, B576, B168, B443

Copper Alloys: Aluminium, Copper, Brass & Gunmetal

Material:- Stainless Steel

- AISI 202, 304, 304L,316, 316L, 310, 410, 420 Etc.

- 4.6 , 5.6, 6.6, 8.8, 10.9 & 12.9 / 'R', 'S', 'T' Conditions.

Alloy Steel:- Bare Condition, Galvanized, Phosphetised, Cadium Plated

Carbon Steel:- Hot Deep Galvanized, Bloodied Etc.

Specification:- We provide Fsateners as per DIN, ANSI, AISI, ASTM, JIS, BS, GOST, IS, Etc. as well as consumers specific requirements. We are specialist in Manufacturing of Drawing Based Fasteners.

Valve Standards: API 598, API 600, API 602, BS 5352, BS 1873, BS 1868, BS 5351, BS 5353, BS 5155, BS 5156, BS 6765, BS 5146, BS 5150, BS 5151, BS 5152, BS, 5153, BS 5157, BS 5160,BS 5840,BS 6364,BS 6683, BS 6755,IS:10189,ANSI B16,MSS-SP 81,MS-SP 55

Manufacturers: Blend steel, Dongyang, Seo-Heung

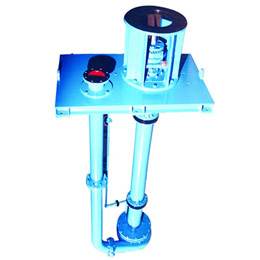

Manufacturers: Sam turbo India, CW Hydro INC, IL Sung pump etc.

| Operating Range | |

|---|---|

| Capacity | upto 4000 m3/hr |

| Head | upto 150m |

| Temperature | upto 220° C |

| Pressure | upto 40 bar |

Design: Horizontal, axially split single stage, inline design volute casing pumps with double suction, radial impeller according to API - 610 7th edition.

Application: This process and transfer pump has been developed for the most exacting conditions and can be used for a multitude of operations such as for pumping crude oil, oil and liquid hydrocarbons, furthermore for pumping cooling water, hot water, river water, brackish water as well as sea water, and also acids and alkalis. This type can also be used for loading in tank farms and as fire water pumps in fire fighting systems.

Materials: Graded cast iron / WCB/CF8/CF8M (SS-316)/317/317L/CD4MCU/Alloy - 20/Hastalloy - B/ Hastalloy - C, and material combination as per API - 610.

| Operating Range | |

|---|---|

| Delivery Size | DN 32 to 200 mm |

| Capacity | upto 750 m3/hr |

| Head | upto 150m |

| Temperature | upto 150° C |

| Pressure | upto 22 bar |

Design: Horizontal, radial split, volute casing pumps according to DIN 24256 with closed impeller, end suction, top centre line discharge. Back pull out design enables to remove the rotor without disturbing the pipelines. If a spacer coupling is used, the motor does not have to be removed from the base plate. Only four bearing beds cover the entire 32 models. This means that the shafts, sleeves, bearings, and bearing beds are identical in and interchangeable for a large number of pump sizes.

Application:

Materials: Graded cast iron / WCB/CF8/CF8M (SS-316)/317/317L/CD4MCU/Alloy - 20/Hastalloy - B/ Hastalloy - C etc.

| Operating Range | |

|---|---|

| Delivery Size | DN 25 to 200 mm |

| Capacity | upto 700 m3/hr |

| Head | upto 180m |

| Temperature | upto 260° C |

| Pressure | upto 26 bar |

Design: Horizontal, radial split, volute casing pumps according to ANSI B73-1 specifications with open impeller, end suction, top centre line discharge. Simple external axial adjustment for impeller wear. Back pull out design enables to remove the rotor without disturbing the pipelines. If a spacer coupling is used, the motor does not have to be removed from the base plate. Only four bearing beds cover the entire 32 models. This means that the shafts, sleeves, bearings, and bearing beds are identical in and interchangeable for a large number of pump sizes.

Application:

Materials: Graded cast iron / WCB/CF8/CF8M (SS-316)/317/317L/CD4MCU/Alloy - 20/Hastalloy - B/ Hastalloy - C etc.

| Operating Range | |

|---|---|

| Delivery Size | DN 25 to 250 mm |

| Capacity | upto 1000 m3/hr |

| Head | upto 300m |

| Temperature | upto 450° C |

| Pressure | upto 60 bar |

Design: Centreline - supported rigid foot arrangement, centreline discharge, back pullout design according to API 7th edition. 3 inch discharge and larger are having double volute to minimize radial thrust. Designed with heavy-duty shaft and bearings. Shaft diameter, bearing span and overhung so engineered to give very low deflection. Renewable impeller and casing wear rings.

Application:

Materials: Graded cast iron / WCB/CF8/CF8M (SS-316)/317/317L/CD4MCU/Alloy - 20/Hastalloy - B/ Hastalloy - C, and material combination as per API - 610.

| Operating Range | |

|---|---|

| Delivery Size | DN 200 to 450 mm |

| Capacity | upto 3000 m3/hr |

| Head | upto 40m |

| Temperature | upto 110° C |

| Pressure | upto 7.5 bar |

Design: Horizontal, single stage, volute casing pumps with discharge branch arranged tangentially upwards/horizontal, flanged to a bearing pedestal. The pump is normally provided with open impeller.

Application:

Materials: Graded cast iron, Bronze and CF8M (SS-316).

| Operating Range | |

|---|---|

| Delivery Size | DN 80 to 350 mm |

| Capacity | upto 2250 m3/hr |

| Head | upto 80m |

| Temperature | upto 140° C |

| Pressure | upto 22 bar |

Design: Heavy duty, horizontal, centrifugal, back pull out design, according to DIN 24256. Open impellers are provided with renewable front wear plate and closed impellers with wear-ring. Simple external axial adjustment for impeller wear.

Application:

The wide passages in the suction zone of the impeller with less number of vanes and non-clogging design helps to handle stocks easily.

Materials: Graded cast iron / WCB/CF8/CF8M (SS-316)/317/317L/CD4MCU/Alloy - 20/Hastalloy - B/ Hastalloy - C etc.

| Operating Range | |

|---|---|

| Delivery Size | DN 32 to 300 mm |

| Capacity | upto 1800 m3/hr |

| Head | upto 150m |

| Temperature | upto 140° C |

| Pressure | upto 22 bar |

Design: Horizontal, single stage, radial split centrifugal pump with back pull out design. Pumps stock like water resulting in substantial power saving. Wear plate - impeller gap is externally adjustable, hence pump performance and efficiency remain high. Open impellers are specifically designed for stock up 8%. Dynamic seal can handle stock upto 8 % without external sealing water. Mechanical seal/packed stuffing boxes are also available. The prefixed rotor with heavy-duty bearings eliminates seal and bearing problems.

Application:

Materials: Graded cast iron / WCB/CF8/CF8M (SS-316)/317/317L/CD4MCU/Alloy - 20/Hastalloy - B/ Hastalloy - C etc.

| Operating Range | |

|---|---|

| Delivery Size | DN 25 to 150 mm |

| Capacity | upto 500 m3/hr |

| Head | upto 50m |

| Temperature | upto 150° C |

Design: Vertical suspended pumps with closed and open impellers, for wet pit or dry pit applications, wear resistant design, overhung impellers. Two bearings support are provided above the base plate and intermediate bush bearings are avoided. Suitable for maximum submersion depth over 2 metres. For more depth, suction spool is used. Self-priming, simple mounting.

Application:

Materials: Graded cast iron /Ni-hard-IV/WCB/CF8/CF8M (SS-316)/317/317L/CD4MCU/Alloy - 20/Hastalloy - B/ Hastalloy - C etc.

| Operating Range | |

|---|---|

| Delivery Size | DN 25 to 300 mm |

| Capacity | upto 900 m3/hr |

| Head | upto 120m |

| Temperature | upto 120° C |

Design: Vertical suspended pumps with closed and open impellers, for wet pit or dry pit applications, wear resistant design, overhung impellers upto 2 metres submersion depth, intermediate bush bearing support for submersion depth over 2 metres. Self-priming, simple mounting.

Application:

Materials: Graded cast iron /Ni-hard-IV/WCB/CF8/CF8M (SS-316)/317/317L/CD4MCU/Alloy - 20/Hastalloy - B/ Hastalloy - C etc.

| Operating Range | |

|---|---|

| Delivery Size | DN 32 to 150 mm |

| Capacity | upto 550 m3/hr |

| Head | upto 100m |

| Temperature | upto 160° C |

| Pressure | upto 16 bar |

Design: Horizontal, radial split, volute casing pumps according to DIN 24255 std. with closed impeller, end suction, top centre line discharge. Back pull out design enables to remove the rotor without disturbing the pipelines.

Application:

Materials: Cast Iron and Bronze.

Manufacturers: Marathon

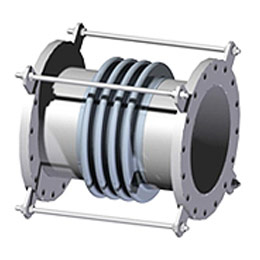

Expansion Joint Standards and Codes: EJMA/ASME/TEMA.

Manufacturers: HKR

Composition if a flexible hose

A flexible hose is generally composed of metal hose, braids, and end fittings such as unions, flanges, nipples, and sockets.

Read more

Single Type Expansion Joint-Un Tied (MSN)

The simplest form of expansion joint, of single bellows construction, designed to absorb all of the movements of the pipe section in which it is installed.

According to operated pressure of a device, this model is manufactured with or without the shrink ring.

Read more

Spool Type:

A full face integral flange design is available in both Single Arch and Multiple Arch Types. These basic types can be manufactured to meet the requirements of the related Code and Standards. These types are available in several construction design series, based on the application pressure requirement.

Read more

Structural Steel Standards/Codes: AISC, AASHTO, AISI, ASTM, AREMA, and ASCE-07

(MS, SS)

View Details

Gloves for all Applications

Coverall for all applications

Foot Protection For All Applications

Head Protection

Respiratory and Breathing protection

Eye And Face Protection

Hearing Protection

Fall Protection

Lanyard

Acoustic Insulation

Matt Insulation

PLC Based Control Panel

Main Distribution Boards Lower And Higher Capacity

Variable Frequency Drive Panel

Waste Water Treatment System